Construction Case Study

Reduced Damages and Increase In Shelf Life Of Materials

When protective packaging is to be used in harsh outdoor environments, material selection is critical.

Here's the stats.

25%

Reduction In Damages

10 Years

Fitament Expectancy

Design

Enabled Easier

Part Replacement

The Company/Background

A leading infrastructure company working across the UK and Ireland who design, develop, build and maintain projects across all transport infrastructure with an extensive fleet of specialist plant. Over the last 14 years the company has grown extensively and now employs 300 people, has offices throughout the UK and Ireland focusing on infrastructure projects and are well established within the railway, airport and power sectors.

A key to their success is the company’s ability to build strong, long-lasting partnerships with their clients whilst producing an efficient, safe and quality product throughout the project cycle. Their highly skilled teams have the knowledge to support the broad spectrum of transport networks keeping passengers and freight on the move.

Our customer offers bespoke engineering solutions to clients across the UK and Ireland who seek an innovative approach to the construction and maintenance of our infrastructure. They pride themselves on being different, challenging themselves to get better solutions and delivering them right, first time.

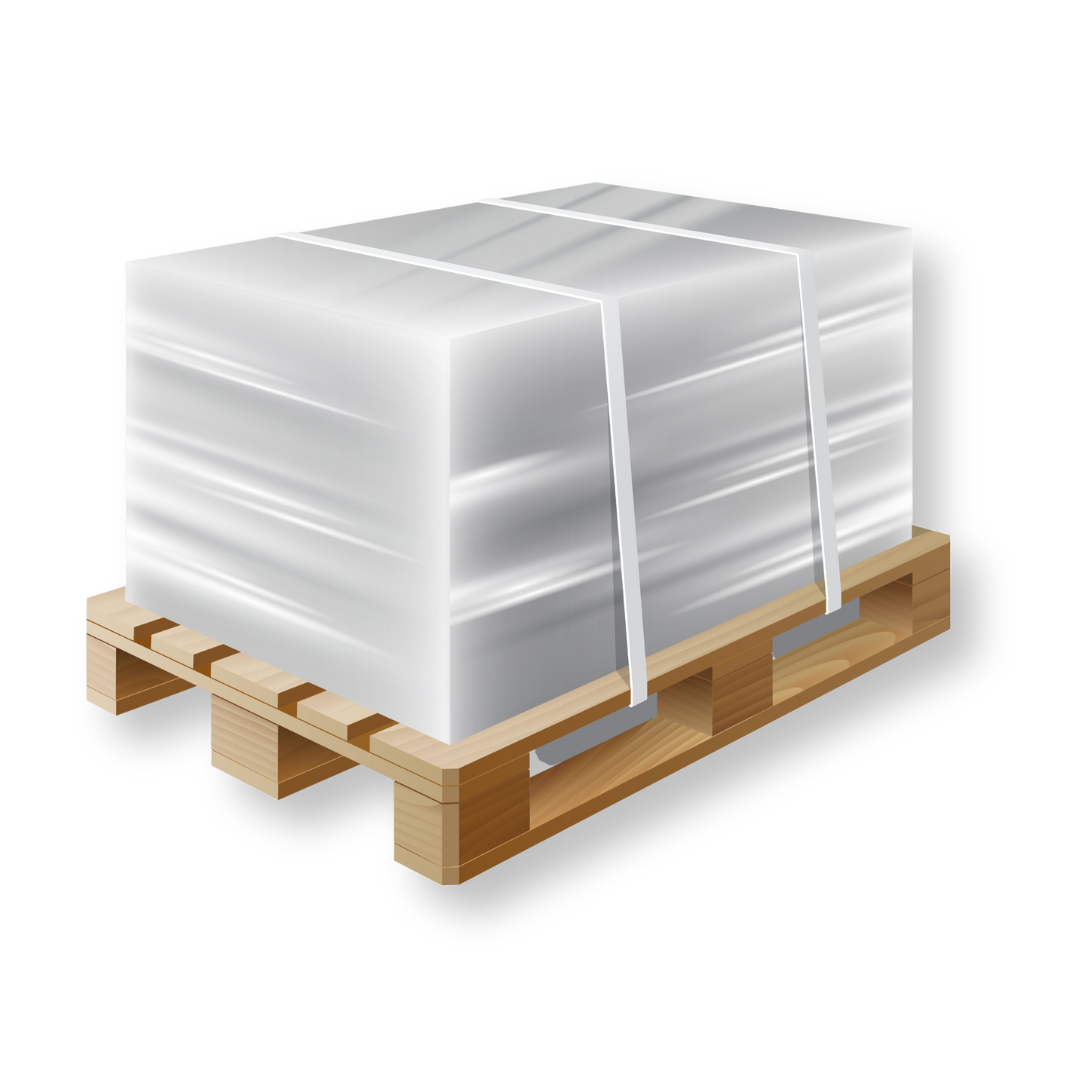

The Challenge

Our customer approached us with an exciting project to assist in the set up for Heathrow Airport T5 Pod guideway transport system. The guideway system is used to transport passengers from the car park to the terminal in unmanned transportation pods. The issue that the customer was facing was that the pods were getting damaged as they turned within the departure area and caught on walls. Synergy Packaging were tasked to produce new corner nosings made from a material that would not damage the pods, would absorb any minor knocks and would be able to withstand the harsh British climate. With the Pods navigating their route using a laser guidance system, it was also important that the nosings were able to reflect the laser effectively.

The solution.

Synergy Packaging designed a full set of nosing part that were able to fit perfectly into the existing set up at Heathrow with some parts measuring up to 5m. We worked very closely with our material supplier to develop the material so that it could withstand UV penetrating the foam, therefore, increasing the life of the material. With the enhancements that we made; the new fitments should last for over 10 years whatever types of weather conditions are thrown at it.

The results.

The Synergy fitment solutions were fitted into place overnight on a very tight timescale and continue to work perfectly, delivering customers to and from the terminal building safely.

A 25% Reduction In Damages

Utilising packaging that was bespoke.

The synergy fitament solutions were fitted into place overnight on a very tight timescale and the solution reduced damages, increased fitment lifetimes and ultimately, gave smoother, safer rides for passengers.

Increased Fitament Lifetimes

10 Year Longevity

Additional fitments, materials and parts were also ordered as a backup should then be needed to be put in place for any disaster plans.

We mean it when we say

for your every needs

Ready to get started?

If you're ready to see all the bespoke solutions we can offer you! It's time to click the button below: