Electronics & IT

Decrease In Cube Size Package In A Cost Effective, Easy-to-use format.

Here's the stats.

20%

Decrease in costs

Increase

In packaging and distribution

efficiences

10%

Reduction in package size

The Company.

The Background.

A leading global online food and beverage company that operates in 22 countries and deals with over 634,000 connected partners. The company developed a point-of-sale device to link front of house with kitchens so that orders could be placed quickly and efficiently. The device was built from the ground upwards and allowed restauranteurs to have greater visibility, control and plan stock levels and give them the ability predict future sales.

The Challenge.

The customer was having problems meeting their ideal price point for the packaging whist retaining a high level of product protection. If the price of the packaging was too high, they feared that their product may not be attractive within the market place that they were targeting. Also, they felt that if the packaging was reduced and did not perform to the required level then the market would pick up on this and the project could be a non-starter. With the product being shipped out as both palletised and individual shipments, the solution needed to be designed to maximise the number of products on a pallet whilst retaining the right level of performance for manually handled, individual shipments.

The

Solution.

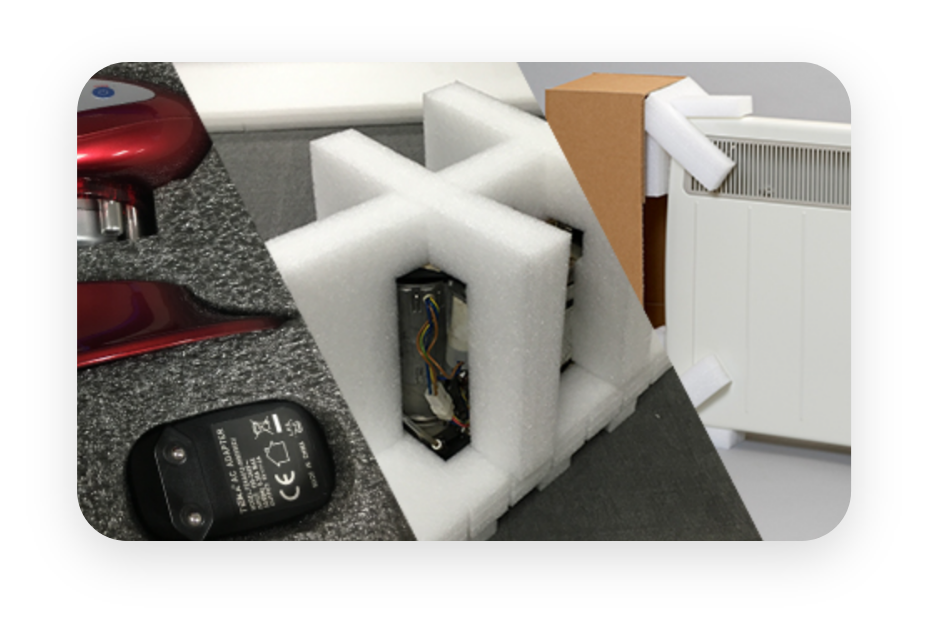

Whilst the original request from the customer was for a like-for-like design purely for a pricing exercise, our team of designers offered the customer an alternative, lower cost solution that performed to the required level for both palletised and individual shipments. Using two engineer designed polyethylene foam end caps with end bars taken from scrap material produced during the pressing cycle, the designers were able to ensure that the minimum amount of packaging material was used whilst still offering the maximum protection to the product.

The Results.

20% cheaper to transport

Cost effective

Due to lower cube size the client was able to ship 20% more products during transportation. Decreasing costs.

Easier for the customer to use

Same packaging bigger impact

Our solution enabled faster packing times and minimised user error due to its simplistic design.

Higher performance

Multi use

The solution offered the correct levels of protection for both palletised and individual shipments

Improved contact with the product

Decreasing damages

With the correct density and amount of packaging material in contact with each surface of the product, the cushioning performance was improved especially for individual shipments where, anticipated shock transfer to the product through vibration or impact is dramatically increased.

Ready to get started?

Book your consultation today with a Synergy Packaging Expert.